Unlocking Business Growth through Cutting-Edge Electronics, 3D Printing, and Innovative Equipment

In the rapidly evolving landscape of modern industry, businesses that harness the potential of advanced electronics, the revolutionary capabilities of 3D printing, and innovative machinery such as the mobile impact crusher are positioned for unprecedented success. As organizations seek competitive advantages, embracing technological innovation becomes not just a choice but a necessity for sustainable growth and market leadership.

Understanding the Foundations of Modern Business Innovation

Business success in today’s digital age hinges upon integrating sophisticated technological solutions into core operational strategies. The domains of electronics and 3D printing have emerged as pivotal sectors that drive innovation, efficiency, and product differentiation. Simultaneously, specialized equipment like the mobile impact crusher plays a crucial role in construction, mining, and recycling industries, enabling companies to undertake large-scale projects with agility and precision.

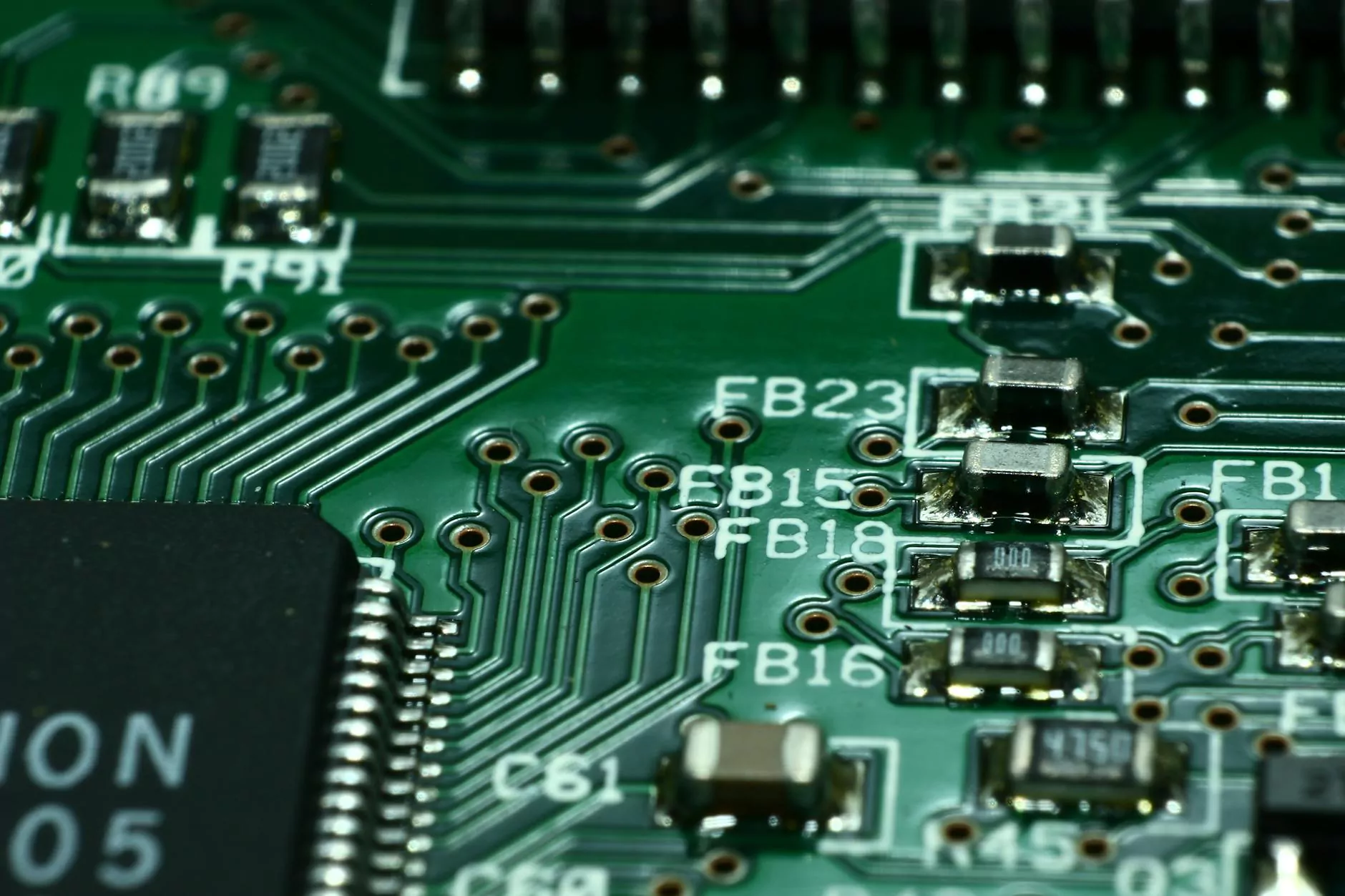

Electronics: The Backbone of Digital Transformation

Electronics form the backbone of modern business infrastructure. From smart sensors and automation systems to IoT (Internet of Things) devices, electronic components streamline operations, reduce costs, and empower data-driven decision-making. The proliferation of electronic innovations has revolutionized supply chain management, customer engagement, and product development.

Leading electronics manufacturers and solution providers focus on delivering high-quality, reliable components that meet industry standards. Leveraging advanced electronics allows businesses to integrate artificial intelligence, machine learning, and remote monitoring into their processes, fostering a highly adaptive and responsive enterprise environment.

3D Printing: Catalyzing Manufacturing Revolution

One of the most transformative developments in recent decades is 3D printing. This technology enables the creation of complex, customized components with precision and speed, drastically reducing lead times and manufacturing costs. It fosters innovation by allowing rapid prototyping and iterative design processes, which are essential for staying ahead in competitive markets.

In manufacturing, 3D printing facilitates on-demand production, minimizes waste, and allows for the development of complex geometries impossible with traditional methods. Businesses in sectors like aerospace, automotive, healthcare, and consumer goods harness 3D printing to boost agility and deliver customized solutions effectively.

Integrating Technologies for Business Excellence

Synergizing electronics, 3D printing, and advanced machinery creates a comprehensive ecosystem that enhances operational efficiency and fosters innovation. This integration enables businesses to develop and produce innovative products faster, optimize supply chains, and expand their market reach.

Role of Innovative Machinery: Spotlight on the Mobile Impact Crusher

In the realm of heavy industry equipment, the mobile impact crusher stands out as a game-changer for construction, demolition, and recycling projects. Its mobility, efficiency, and adaptability allow companies to maximize productivity and reduce environmental impact. Built with rugged durability and technological sophistication, the mobile impact crusher can process large volumes of materials on-site, significantly reducing transportation costs and project timelines.

This machine exemplifies how state-of-the-art equipment, when combined with cutting-edge electronics and 3D-printed spare parts, can elevate project results and generate competitive advantages. It also demonstrates how innovation extends beyond product design into operational logistics and environmental sustainability.

Advantages of Utilizing Advanced Equipment in Business Operations

- Increased Efficiency: Automating processes with electronic controls and utilizing versatile machinery like the mobile impact crusher enables faster project completion.

- Cost Savings: Reduced transportation and labor costs through on-site processing and innovative manufacturing methods.

- Environmental Sustainability: Machines designed for minimal emissions and waste support eco-friendly business practices.

- Flexibility & Mobility: Equipment such as mobile impact crushers can adapt to diverse site conditions, expanding project capabilities.

- Enhanced Product Quality: Precision manufacturing and real-time monitoring improve the quality and consistency of end products.

Strategic Considerations for Businesses Embracing This Technological Ecosystem

Investing in the right technology begins with understanding operational needs and future growth goals. Companies should prioritize:

- Research & Development: Stay updated with latest innovations in electronics, 3D printing, and heavy machinery.

- Partnerships with Reliable Suppliers: Collaborate with manufacturers like Polygonmach that specialize in integrated solutions.

- Training & Workforce Development: Upskill employees to operate advanced systems efficiently.

- Environmental & Regulatory Compliance: Ensure all equipment and processes meet environmental standards and safety regulations.

- Scalability & Flexibility: Choose solutions that can grow with your business and adapt to changing market demands.

Polygonmach: Leading the Way in Innovative Business Solutions

As a pioneer in the industry, Polygonmach specializes in providing high-quality electronic systems, 3D printing solutions, and advanced machinery such as the mobile impact crusher. Their commitment to innovation and excellence helps businesses optimize operations, reduce costs, and accelerate product development cycles.

Polygonmach’s integrated approach offers:

- Customized electronic automation solutions tailored to specific industry needs.

- State-of-the-art 3D printing technology for rapid prototyping and complex parts manufacturing.

- Robust and versatile mobile impact crushers designed for maximum mobility and efficiency in challenging environments.

- Dedicated support, training, and maintenance services to ensure optimal performance.

Future Trends in Business Innovation: Embracing a Technology-Driven Future

Looking ahead, the global business landscape will increasingly rely on:

- Smart Manufacturing: Integration of IoT, AI, and robotics to create autonomous, self-optimizing production lines.

- Customization & Personalization: Leveraging 3D printing and electronics for bespoke product offerings at scale.

- Sustainable Technologies: Adoption of environmentally sustainable machinery and processes to meet stricter regulations.

- Data-Driven Decision Making: Utilizing electronic systems and sensors to gather actionable insights for continuous improvement.

Businesses that proactively embrace these evolving technologies will position themselves as leaders in their respective sectors, gaining a competitive edge now and into the future.

Conclusion: Building a Resilient and Innovative Business Ecosystem

In conclusion, the integration of electronics, 3D printing, and advanced machinery like the mobile impact crusher represents the future of business innovation across diverse industries. Companies that strategically invest in and adopt these technologies will unlock new levels of efficiency, sustainability, and competitiveness. Partnering with industry leaders such as Polygonmach ensures access to cutting-edge solutions, expert guidance, and ongoing support, empowering businesses to thrive in the modern economy.

Whether you are expanding your manufacturing capabilities, optimizing construction projects, or exploring new product development avenues, understanding and leveraging these technological trends will pave the way for long-term success and growth. The future belongs to those who innovate with purpose and foresight, transforming challenges into opportunities through technology.