The Indispensable Role of Diesel Fuel Pump Manufacturers

In the ever-evolving landscape of the automotive and industrial sectors, diesel fuel pump manufacturers play a pivotal role. These manufacturers are at the forefront of innovation, ensuring that diesel engines operate smoothly and efficiently. Understanding their significance, the quality of their products, and how they influence the supply chain is essential for businesses and consumers alike.

What is a Diesel Fuel Pump?

A diesel fuel pump is a critical component in diesel engines, responsible for transporting fuel from the tank to the engine. Its functionality directly impacts engine performance, efficiency, and longevity. There are several types of diesel fuel pumps, each designed for specific applications:

- Mechanical Fuel Pumps: These pumps are typically used in older diesel engines, relying on engine crankshaft motion to operate.

- Electrical Fuel Pumps: More common in modern diesel engines, these pumps use electricity to move fuel, providing consistent pressure and flow.

- Common Rail Fuel Pumps: Designed for advanced diesel engines, these pumps allow for high-pressure fuel injection, enhancing efficiency and power.

Significance of Diesel Fuel Pump Manufacturers

The role of diesel fuel pump manufacturers is multifaceted and extends beyond merely producing pumps. Here are several reasons why they are indispensable:

1. Quality Assurance and Standards

Manufacturers adhere to strict quality control measures and industry standards. This ensures that every component produced meets the necessary specifications, which is crucial for performance and safety. Reliable manufacturers will often have certifications such as ISO 9001, signifying their commitment to quality management.

2. Innovation and Technology

Continuous investment in research and development enables manufacturers to innovate. They are responsible for creating pumps that are not only efficient but are also environmentally friendly. With stricter emissions standards, the evolution of diesel fuel pumps is critical.

3. Aftermarket Support and Spare Parts Supply

A reliable manufacturer provides excellent aftermarket support, offering spare parts and servicing options. This is essential for maintaining diesel engines and ensuring longevity. A robust partnership with spare parts suppliers like those found at client-diesel.com guarantees that businesses can keep their fleets operational and efficient.

Choosing the Right Diesel Fuel Pump Manufacturer

When it comes to selecting a diesel fuel pump manufacturer, several factors should be considered to ensure that you make the right choice:

- Reputation and Experience: Look for manufacturers with a solid track record in the industry.

- Product Range: A wider variety of products ensures that you can find the right pump for your specific application.

- Quality of Materials: Only partner with manufacturers that use high-grade materials to enhance durability and performance.

- Customer Reviews and Testimonials: Feedback from previous clients can provide insight into the manufacturer’s reliability and product efficacy.

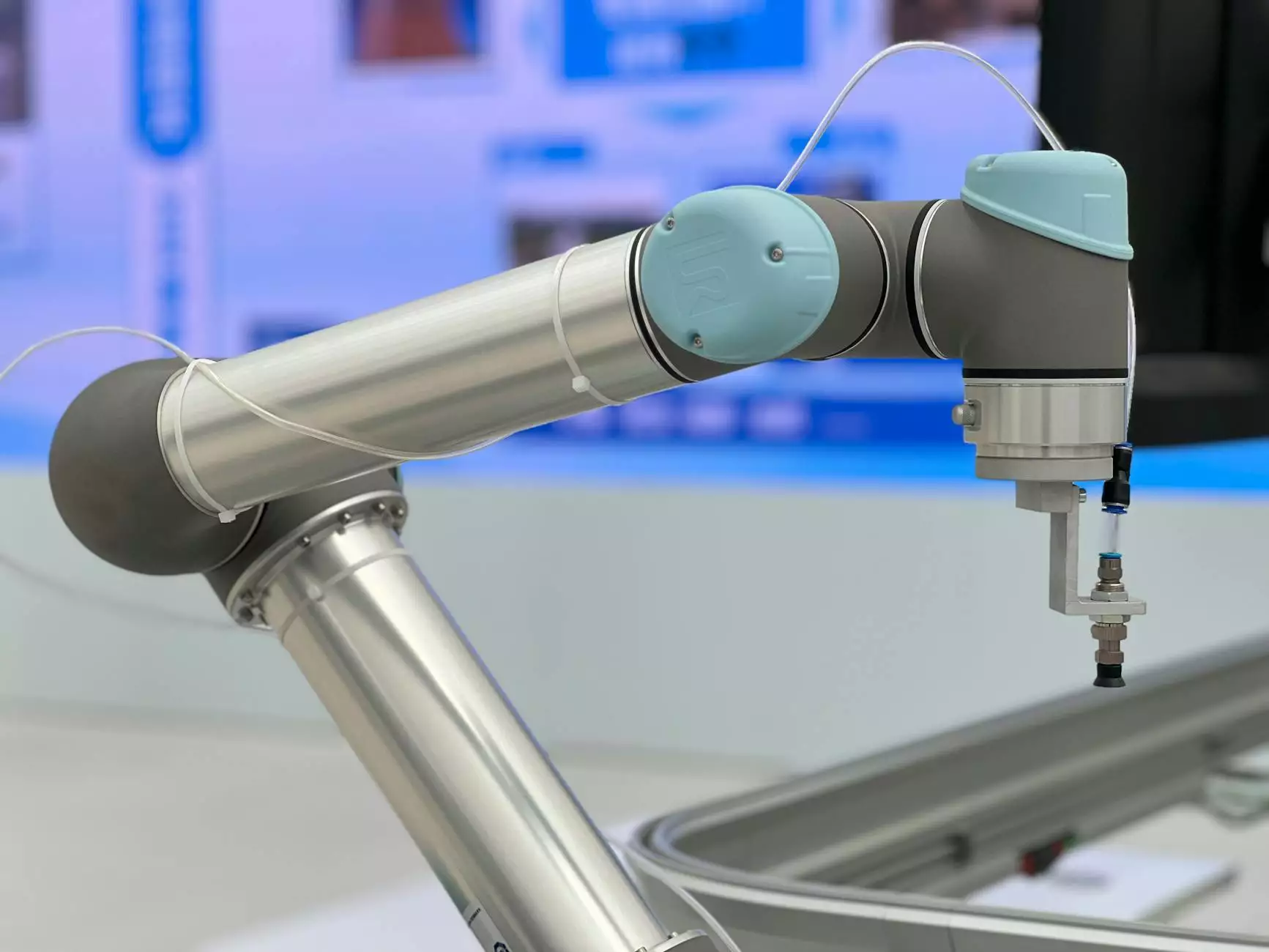

The Manufacturing Process of Diesel Fuel Pumps

The process of manufacturing diesel fuel pumps involves several critical stages:

1. Design and Engineering

Initially, pumps are designed using advanced software that simulates various conditions. Engineers focus on ensuring that pumps will operate under varying pressures and temperatures.

2. Material Selection

The choice of materials is crucial for performance and longevity. Common materials include:

- Stainless Steel: Used for its corrosion resistance and strength.

- Aluminium: Lightweight and good for most operational conditions.

- Composite Materials: Used to reduce weight and improve fuel efficiency.

3. Manufacturing Techniques

Manufacturers employ several techniques including machining, molding, and assembling components to create the final product. Each method must be precisely executed to ensure optimal performance.

4. Quality Control Testing

After production, the pumps undergo rigorous testing to validate their functionality. Tests may include pressure tests, flow rate checks, and durability assessments.

The Future of Diesel Fuel Pump Manufacturing

As the automotive industry shifts towards greener technologies, diesel fuel pump manufacturers are also adapting. The incorporation of alternative fuels and advancements in pump technology is crucial in meeting environmental regulations. This evolution presents several opportunities:

1. Hybrid and Electric Vehicles

As hybrid vehicles gain popularity, manufacturers are exploring how diesel fuel pumps can be optimized for such technologies, including efficiency adaptations for dual-engine systems.

2. Biodegradable Fuels

The rise of biodiesel and other renewable diesel blends requires manufacturers to design pumps that can handle fluctuating fuel properties without compromising performance.

3. Automation and Smart Technologies

The integration of IoT in pump manufacturing allows for real-time monitoring and adjustments, improving efficiency and reducing the risk of failures.

Partnering with Diesel Fuel Pump Manufacturers

For businesses relying heavily on diesel engines, forging strong partnerships with reputable diesel fuel pump manufacturers is a strategic move. Such partnerships provide:

- Access to Latest Technologies: Staying ahead in terms of equipment can lead to enhanced performance and reduced operational costs.

- Expertise and Support: Manufacturers often provide technical support and training for staff, ensuring they can maintain and troubleshoot equipment effectively.

- Cost-Efficiency: By relying on high-quality pumps, businesses can minimize the frequency of repairs and replacements, leading to significant cost savings in the long run.

Conclusion

In summary, diesel fuel pump manufacturers are essential to the functioning of diesel engines across various industries. Their commitment to quality, innovation, and customer support ensures that businesses can rely on them to meet their operational needs effectively. As the industry continues to evolve, staying informed about the latest trends and technologies in diesel fuel pumps will be paramount for business success.

For companies looking to source high-quality diesel engine parts and components, a partnership with a trusted supplier like client-diesel.com can be a game-changer, providing the necessary support and products to keep your operations running smoothly.